Custom Resistive Touch Screen

Custom Touch Screen

Jul-08-2024

Advantages of resistive touchscreens.

Enhance your industrial processes with Wanty Touch’s Custom Touch Solutions. Designed for optimal performance and versatility, our bespoke touch displays and computing solutions seamlessly integrate with your existing infrastructure, providing an exceptional user interface and boosting operational productivity.

•Resistive touchscreens are highly accurate down to the pixel dot level and are suitable for resolutions up to 4096×4096.

•The screen is resistant to dust, moisture, and oil, making it suitable for use in both low and high-temperature environments.

•Resistive touch screens utilize pressure sensing, allowing interaction with any object, including gloves, and supporting handwriting recognition.

•Resistive touchscreens are also more affordable due to their mature technology.

Disadvantages of resistive touchscreens.

•Resistive touch screens typically support single-point touch. When designed for multi-touch, pressing two points simultaneously can cause pressure imbalances, leading to touch errors and making multi-touch functionality more challenging to achieve.

•Resistive touch screens are more prone to damage from scratches and other factors, which can impact their touch functionality and appearance.

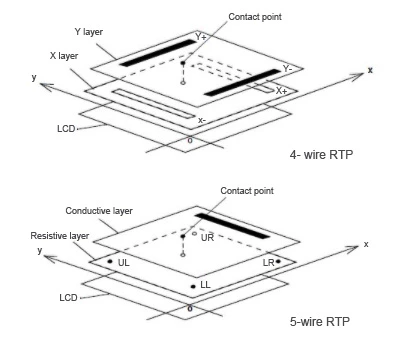

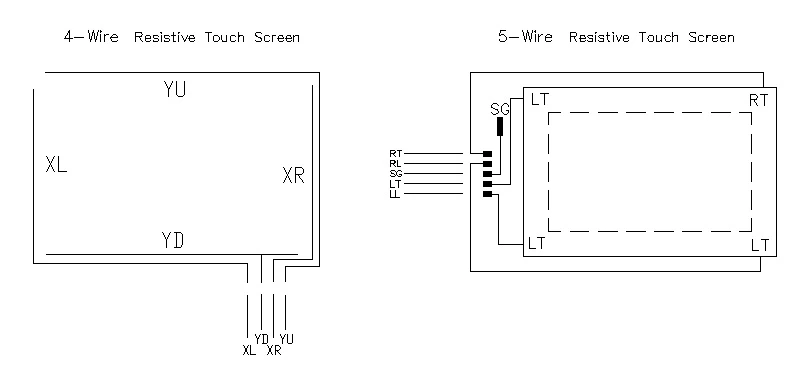

4-wire resistive touch modules

4-wire RTP offers a cost advantage. It features an Indium Tin Oxide (ITO) resistive coating on the inside of the touch layer to form the X and Y axes. When pressure is applied, the voltage changes, allowing the coordinates of the X and Y axes to be calculated using a voltage divider.

A disadvantage of the 4-wire RTP is that certain factors, such as external environmental conditions and high-frequency operation, can degrade the linearity and accuracy of the X and Y axes.

Occasional recalibration may be necessary to maintain touch point accuracy. Additionally, because the top layer is a thin film, scratches and nail marks become more visible with extended use.

5-wire resistive touch modules

The structure and design philosophy of a 5-wire RTP are similar to that of a 4-wire RTP. In a 5-wire resistive touch screen, only the bottom layer, known as the resistive layer, is used to generate the X and Y axis coordinates. The top layer acts purely as a conductive layer, typically made from nickel-gold plated material for enhanced durability. Since the top layer does not contribute to the axis generation, this design provides excellent stability, durability, sensitivity, and reliability.

Some advantages of the 5-wire RTP include maintaining a constant level of accuracy even if the top layer is damaged and ensuring that tactile response and accuracy are not affected by harsh environmental conditions. However, it is more expensive and more difficult to manufacture.

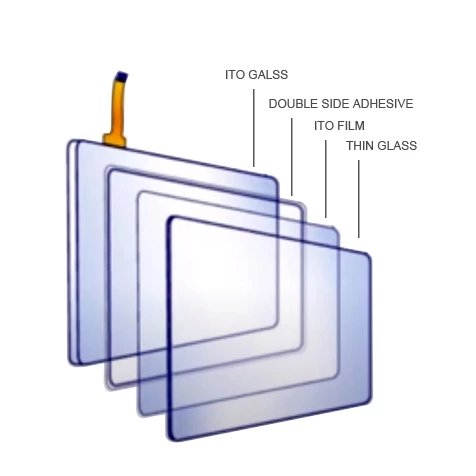

G+G Resistive Touch Modules

G+G resistive touch modules offer an ideal solution for using RTP in harsh environments where corrosive solvents and liquids can damage the ITO film. Although this is a more complex process, we have experience handling small quantities.

Related Topics

Custom Resistive Touch Screen

Jul-08-2024

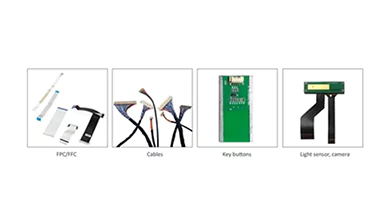

Matching accessories

Jul-08-2024

LCD boards Add-Ons

Jul-08-2024

Low Cost All Viewing Solution

Jul-08-2024

Get a Free Quote

✔ 16 Years Manufacture Service ★★★★★

✔ 3 Technical Experts And 52+ Project Engineers Will Assiste You

✔ Wanty Employs Over 52 Engineers, Many Of Whom Come From Leading Tft Lcd Module Companies Such As Tianma And Boe-Varitronix. Each Core Team Member Brings 15 Years Of Industry Experience.

✔ If you would like more information about our products and services, please contact us. Whether you need a standard solution or a customized one, we are here to meet your needs.

✔ Please complete the form below, and the selected location will contact you promptly. Thank you for visiting, and have a great day!