Tft LCD Backlight Module Customization

Custom Touch Screen

Jun-24-2024

The backlight is a crucial component of the LCD module. Unlike OLED displays, TFT LCD panels do not emit light themselves; they are passive devices. As transmissive panels, TFT LCDs require a backlight to provide illumination. A high-quality backlight module ensures even lighting, resulting in a more uniform and detailed display for the TFT LCD module.

Wanty can customize backlights to various specifications. Beyond mechanical aspects like size and shape, we have extensive experience in adjusting brightness levels, NTSC, color, drive circuits, heat dissipation, lifespan, power consumption control, and cable configurations.

Brightness:

Our backlights can range from 100 to 2000 nits, depending on size and structure. Most products can achieve up to 1000 nits, ensuring sunlight readability.

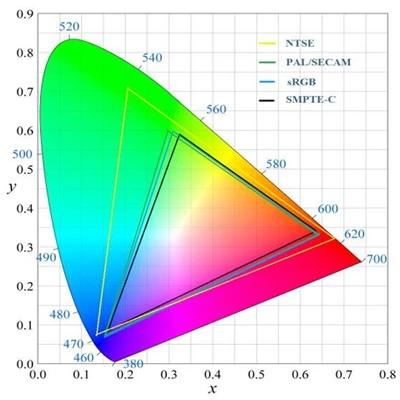

NTSC:

In the traditional backlight industry, significantly increasing the NTSC value is challenging. However, we have been experimenting with quantum dot technology, which easily surpasses 100% NTSC. This enhancement results in more vivid pictures and smoother color transitions.

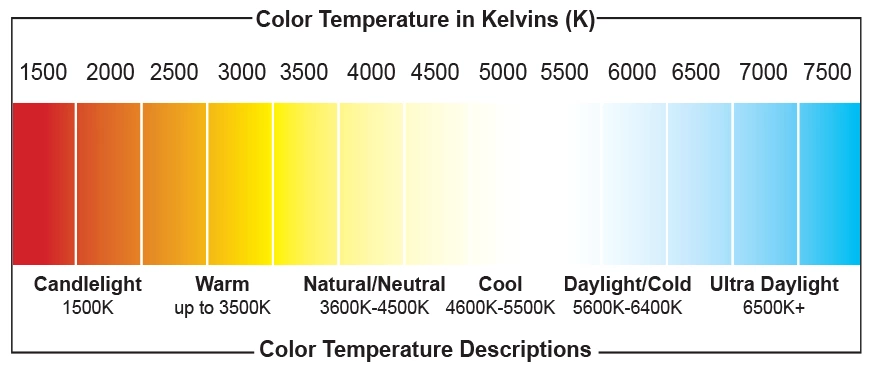

Colour Temperature in Kelvins:

The most widely used backlight for TFT LCDs is white. Within this, options include positive white at around 5500K, warm white (yellowish) at 3500K, and cool white (cold) at 6500K. Depending on your preference or UI settings, we can select the appropriate LED color or a combination of colors.

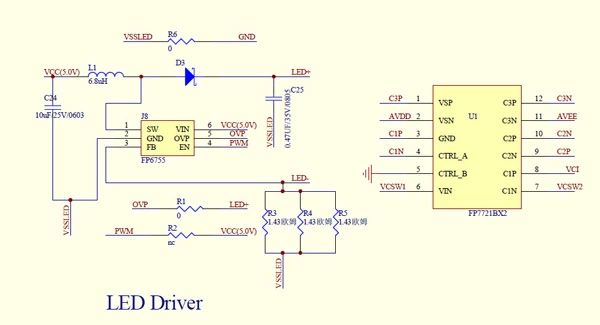

Driver circuit:

Small backlights typically require relatively low voltage and current, which most motherboards can supply adequately. However, products with high brightness requirements or larger sizes may contain dozens of LEDs, necessitating very high voltage or large currents. For these cases, a backlight drive circuit is essential. We provide the necessary drive circuit to match the customer’s output requirements, reducing the secondary development cycle.

Heat dissipation:

High-brightness products often have significant power consumption and increased heat generation, necessitating an effective heat dissipation structure. This must be factored into the backlight design, incorporating elements such as a well-designed heat dissipation structure, heat dissipation film, and the use of aluminum substrates to ensure optimal performance and longevity.

Power consumption:

Compared to TFT LCDs, backlights consume significantly more power, often being the largest power-consuming component of an LCM. Some customers prioritize lower power consumption over brightness, especially for battery-powered handheld products. To address this, we can enhance brightness without increasing power consumption by using additional films, such as DBEF (Dual Brightness Enhancement Film) and other brightening films.

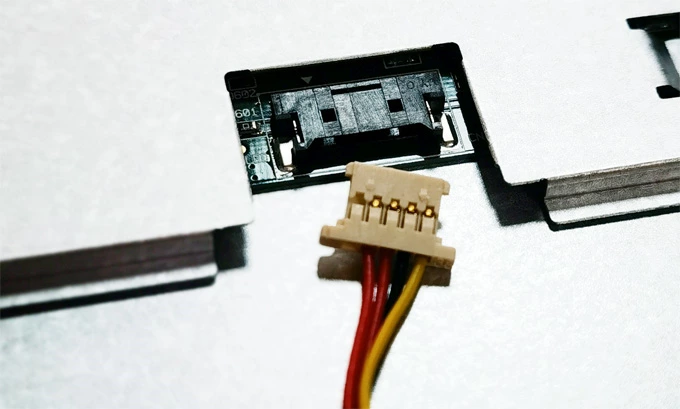

Cables:

Backlighting also requires cables, which can be connected either through an FPC to the LCD’s FPC and controlled via a port, or through a separate cable controlled by a connector. The choice depends on your product’s structure. For higher current requirements, we prefer using a separate cable for control, as it provides greater security and stability.

Related Topics

Custom Resistive Touch Screen

Jul-08-2024

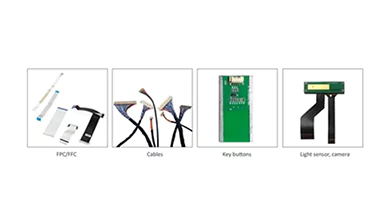

Matching accessories

Jul-08-2024

LCD boards Add-Ons

Jul-08-2024

Low Cost All Viewing Solution

Jul-08-2024

Get a Free Quote

✔ 16 Years Manufacture Service ★★★★★

✔ 3 Technical Experts And 52+ Project Engineers Will Assiste You

✔ Wanty Employs Over 52 Engineers, Many Of Whom Come From Leading Tft Lcd Module Companies Such As Tianma And Boe-Varitronix. Each Core Team Member Brings 15 Years Of Industry Experience.

✔ If you would like more information about our products and services, please contact us. Whether you need a standard solution or a customized one, we are here to meet your needs.

✔ Please complete the form below, and the selected location will contact you promptly. Thank you for visiting, and have a great day!